Respiratory Protection on the Job

Workers can be exposed to health hazards from the air such as dusts, chemicals, or reduced oxygen environments, depending on the task or the environment they are working in. If engineering and administrative controls are unable to control the airborne hazards, respiratory protection and the appropriate cartridges must be used to protect exposed workers.

Types of Respiratory Protection

When looking at respiratory protection, there is a lot to choose from. Respirators need to fully protect the worker from the airborne hazard of concern.

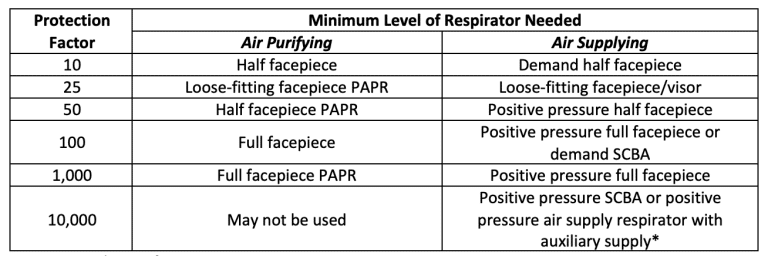

The chart below shows the different types of respirators and their associated protection factors (PF).

PAPR = Powered Air Purifying Respirator

SCBA = Self-Contained Breathing Apparatus

*Supplied air respirator with an additional air supply (usually a cylinder) used should the primary air supply fail

The protection factor (PF) indicates the level of protection above the 8-hour OEL that the respirator provides. For example, a half facepiece air purifying respirator (PF=10) protects against up to 10X the 8-hour OEL of an airborne contaminant.

Respiratory Protection: Cartridge Selection

Once you know the hazards your workers face, you can select the appropriate cartridge that will filter the contaminants out of the worker’s breathing air. Each brand has their own way of classifying what cartridge will protect against what hazard, so you must ensure you are choosing the right one. Cartridge change out frequency depends on the duration of the work shift, as well as the exposure level.

Code of Practice

With the use of respirators, employers must include a written Code of Practice for the use of Respiratory Protective Equipment. The code must provide a detailed explanation of the selection, maintenance and use of the respiratory protective equipment at the job site. This Code of Practice must be re-evaluated as needed.

Exposure Monitoring

The best way to ensure the correct respirator type is chosen is to conduct exposure air monitoring at the worksite. This is where we come in! Air monitoring is specific to each job site, the number of tasks being completed, and the airborne hazards each task presents. After the testing is completed, we can provide an expected exposure level for each task that allows for precise recommendations to ensure your workers are fully protected.

Allow us to Explain Further

If you have questions about respiratory protection, air monitoring, exposure or are interested in having an air assessment completed at your workplace, contact JADA Solutions (HSE) Inc. We have the equipment, expertise, and experience to help you measure the exposure level of airborne hazards in your workplace and make sense of the results! Please refer to our description of services in the meantime!

Reach Out to Our Team!

How Can We Help You?

Contact us at JADA Solutions (HSE) Inc. to speak with one of our professionals!

Newsletter

What is Sick Building Syndrome? 🏢

Learn about some common causes, risk factors and prevention methods in our latest blog post:

#sickbuildingsyndrome #indoorairquality #iaq #hseblog

Did you know that March is Workplace Eye Safety and Wellness Month? 👀

Our latest blog post covers common risks & tips for optimal Eye Health and Safety. ✍

Learn more:

-

#eyehealth #eyesafety #eyewellness #healthandsafety #hse