The Importance of Decontamination

Recently, I was at a chemical site to conduct a site inspection and air monitoring. At the site, workers were removing ceramic refractory fibre (CRF), and a decontamination area was set up. Eventually, a worker brought a big chunk of material containing CRF outside of the containment and had it sitting in a public area without following any decontamination procedure. This resulted in the job being paused for the contaminated area and reevaluated for the CRF removal process. Missteps like this lead to extra time and money being consumed, and put those on site at risk..

So, Why is it Important to Follow the Decontamination Procedure?

As defined, decontamination is the combination of processes that remove or neutralize contaminants that have accumulated on personnel and equipment. This is essential to health and safety at a hazardous waste site because decontamination can lower exposure to harmful materials. In other words, effective decontamination reduces the risk of harm to those directly affected, and prevents further spread of contamination to other people and/or equipment.

Depending on the substance involved and the environment in which the work is being carried out, different decontamination methods may be used:

Physical removal can be but is not limited to:

Chemical Removal can be but is not limited to:

• Dissolving them in a solvent [Dilute Acids for Basic (caustic) compounds, Dilute Bases (for example detergent, soap) for Acid compounds]

A Decontamination Plan Should be Developed as Part of the Site Safety Plan

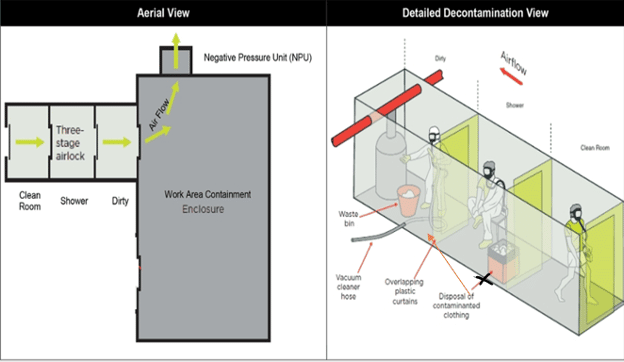

Decontamination protects all site personnel by minimizing the transfer of harmful materials into clean areas. For example, as listed in the Alberta Asbestos Abatement Manual, “decontamination facilities including a dirty room, shower room, equipment transfer area and clean room may be constructed for personnel leaving the work area or wastes that must be removed from the work area.” This area is constructed to prevent the spread of hazardous fibres beyond the work area.

There are steps workers may need to follow:

- Gently remove clothing (Tyvek suits) slowly, turning arm sleeves and pants legs inside out during the process and dispose of it in an approved disposal bag in the dirty room

- Take a warm shower and gently wash with soap. Wipe down your PPEs and place them in a plastic bag

- Put on clean clothes and store individual respirators in a clean room

- Airflow towards the dirty area in both the shower room and clean room

Decontamination is an essential part of any infection prevention and control program.

Here is the layout of the decontamination facility for asbestos abatement:

Questions or Concerns? We Want to Hear from You!

How Can We Help You?

Contact us at JADA Solutions (HSE) Inc. to speak with one of our professionals!

Newsletter

📹 Watch our latest Safety Toolbox Talk: Mould and Fungi 101: Viable vs. Non-Viable Mould Testing

💡Are all moulds considered fungi? And why should we care? This leads us to explaining the two different types of testing for mould exposure: viable vs non-viable.

🔍 Lead and Heavy Metal Exposure: Are You Protecting Your Workers?

Lead and other heavy metals can quietly put your team at serious risk - especially during construction, demolition, or manufacturing projects.

Our last Asbestos Worker in Alberta 2-Day Training Course before the Summer season happens at the end of this month!

🗓️ June 24th - 25th

⏰ 8AM - 5PM

💵 $525

📍 Sherwood Park, AB

Claim your spot now! 👉