Crystalline silica is a naturally occurring mineral most commonly found as quartz. Silica is present in substantial quantities in sand, sandstone, granite, stone and rock aggregates, clay, shale, and slate. When crystalline silica is released into the air as fine dust, workers may inhale the dust, putting them at risk for illness.

When breathing in very small (“respirable”) crystalline silica particles, workers are at an increased risk of developing multiple diseases, including:

- Silicosis, an incurable lung disease that can lead to disability and death;

- Lung cancer;

- Chronic obstructive pulmonary disease (COPD); and

- Kidney disease.

Importance of Silica Air Samples

When dust-creating activities are happening, the best way to determine the concentration of dust in the air is to take silica air samples. There are two types of air sampling: personal (occupational) sampling and area sampling.

What do we need for a sample?

- Match-weighted 5µm 37mm PVC Cassette

- Cyclone (Respirable Silica)

- Cyclone Calibrator-Adapter or Calibration-Jar

- Low Flow Sampling Pump (1-4 LPM)

What are the Key Steps?

What Exposure Controls are Neccessary?

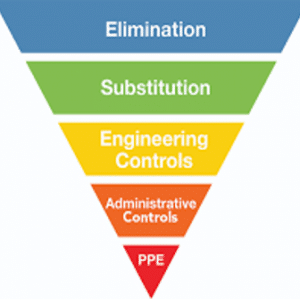

For controlling silica dust, follow the hierarchy of controls for the basic approaches:

It is an employers’ responsibility to protect their workers’ health and safety. Workers who may be exposed to silica are required to undergo a health assessment no more than 30 days after a worker becomes exposed and every 2 years after the initial assessment.

How Can We Help You?

Contact us at JADA Solutions (HSE) Inc. to speak with one of our professionals!

Newsletter

📹 Watch our latest Safety Toolbox Talk: Mould and Fungi 101: Viable vs. Non-Viable Mould Testing

💡Are all moulds considered fungi? And why should we care? This leads us to explaining the two different types of testing for mould exposure: viable vs non-viable.

🔍 Lead and Heavy Metal Exposure: Are You Protecting Your Workers?

Lead and other heavy metals can quietly put your team at serious risk - especially during construction, demolition, or manufacturing projects.

Our last Asbestos Worker in Alberta 2-Day Training Course before the Summer season happens at the end of this month!

🗓️ June 24th - 25th

⏰ 8AM - 5PM

💵 $525

📍 Sherwood Park, AB

Claim your spot now! 👉