You might have heard about it before, but what exactly is the hierarchy of controls?

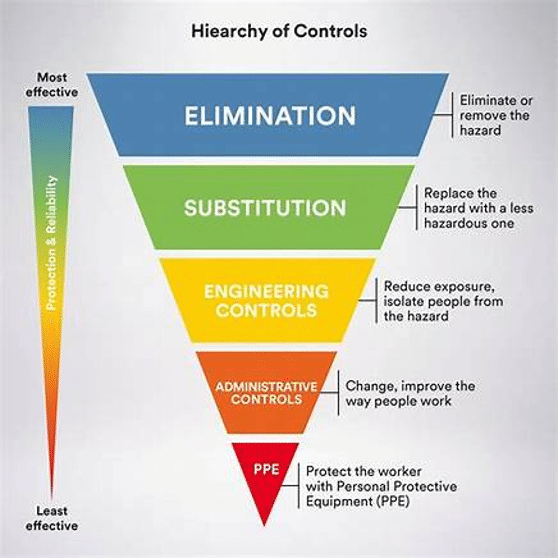

The hierarchy of controls outlines the controls used to mitigate a hazard from most effective to least effective. Hierarchy of controls is essential to workplace health and safety, and it is the base of the environment, health and safety programs used across all different industries. When considering lowering the risk, we should use the most effective way instead of the easy way.

There are five steps in the hierarchy of controls from most effective to least effective:

Elimination > Substitution > Engineering Control > Administrative Control > Personal Protective Equipment

HOC Explained:

Elimination: First approach is always to eliminate the hazard completely. This is the best option for improving safety in your workplace and the most effective control. Different example of elimination will be;

Respiratory: Volatile Organic Compounds (VOCs) include a variety of chemicals that can cause nose and throat irritation. Eliminating the use of products that produces VOCs.

Skin exposure: Eliminate the use of the chemical that is hazardous to health and can cause irritation and burn on skin.

Substitution: If you can not eliminate the hazard, substitute it with less hazardous products or material or equipment.

Respiratory: Use materials and products that do not give off VOCs such as paints and varnishes that are labelled as containing low VOCs.

Skin exposure: A chemical that causes reversible inflammatory effects on living tissue at the site of contact, for example, using less strong solvents.

Engineering Control: The third most effective way to control a hazard is by implementing an engineering control. If you can’t eliminate the hazards or substitute safer alternatives, engineering controls are best options.

Respiratory: Automated paint booth can be used to eliminate the exposure on worker as well as installing the local ventilation will dilute the concentration on the vapors in the work area.

Skin exposure: Installing clear shields with glove bag to handle the chemical or other mechanical way to pour or handle chemical instead of manual handling.

Administrative Control: When you’re unable to implement any of the above control it’s important to put administrative controls into place. Administrative controls can include warning labels, updating company policies, implementing training programs and safe work procedures so your workers can perform their job duties safely.

Work permit, SDS, exposure limit, lock out tag out are also examples of the administrative controls.

Personal Protective Equipment (PPE): The last approach to protect against the hazards. It will not eliminate the hazards but lessen the effect of the hazards.

Respiratory: A respirator is used while working with products that produce vapours, fumes, gases and dust particulate. Different types of respiratory protection are used based on the contaminant and work environment.

Skin exposure: Coveralls, gloves, safety glasses, face shied and rubber boots can be used while manually handling the chemical products.

Based on the work environment or nature of the hazard, sometimes more than one controls are used in conjunction with each other to protect the workers.

If you have questions or concerns around the Hierarchy of Controls at your workplace, please reach out to our team of experts below!

How Can We Help You?

Contact us at JADA Solutions (HSE) Inc. to speak with one of our professionals!

Newsletter

📹 Watch our latest Safety Toolbox Talk: Mould and Fungi 101: Viable vs. Non-Viable Mould Testing

💡Are all moulds considered fungi? And why should we care? This leads us to explaining the two different types of testing for mould exposure: viable vs non-viable.

🔍 Lead and Heavy Metal Exposure: Are You Protecting Your Workers?

Lead and other heavy metals can quietly put your team at serious risk - especially during construction, demolition, or manufacturing projects.

Our last Asbestos Worker in Alberta 2-Day Training Course before the Summer season happens at the end of this month!

🗓️ June 24th - 25th

⏰ 8AM - 5PM

💵 $525

📍 Sherwood Park, AB

Claim your spot now! 👉