PPE Lifespan

Many manufacturers will offer a warranty period of at least one year, covering any sort of product failure. Their products may also include information tags, detailing life expectancy.

How do you decipher the lifespan of your PPE?

It is the responsibility of the user to always inspect PPE before use to ensure it is in good working condition. That being said, your PPE also has an expiry period/date, at which point its ability to deliver the protection it was designed for is compromised.

The PPE life span will also depend on the usage rate, the environmental factors (indoor or outdoor) and the levels of UV, chemical, dirt and sweat exposure. Storage is also a major factor that affects the life span of your PPE.

Here we will talk briefly about when it may be time to replace your PPE:

Safety Shoe: The average life span of safety footwear is minimum one year. However, the actual lifespan is also dependent on the frequency of wearing as well as the work environment. Also, when used in wet conditions, safety footwear will wear and tear at a faster rate.

Shoes and boots start to show wear and tear somewhere around the 1500 km mark under average usage – which is about one year of daily wear. The first thing you need to keep a look out for is wear and tear. If the steel toe of your safety shoe is visible, or you can see the metatarsal guard of your safety shoe. As well, if the insoles of your shoes are beginning to come off. If your answer to all of these questions is a clear “yes”, then it is time for you to purchase a new pair.

Respirator: According to Honeywell there is no life expectancy of a respirator mask. That is – if the user follows the manufacturer’s guideline for using, cleaning, sanitizing and storage. However, the filter and/ or cartridge will be required to replaced. A “filter” is a component used in respirators to remove solids or liquid aerosols (e.g., particulates) from inhaled air.

A “cartridge” as a container with a filter, sorbent or catalyst – or any combination of the three – that removes specific contaminants from air passed through the container.

According to OSHA, the filter needs to be replaced when:

- The user has difficulty breathing comfortably or notices an increase of breathing resistance resulting from particle buildup.

- The filter becomes visibly dirty.

- The filter is physically damaged.

Safety glasses: Most safety glasses can technically last up to 3 years, however it also depends on the usage and type of work. In high-dust environments containing metal grinding sparks, dirt, sawdust, or other airbourne particulates safety eyewear can be gradually scratched over time, creating a sort of obscurity that impairs visibility. It is important to check for damage regularly before each shift, at minimum. Any scratched, broken, bent, or ill-fitting glasses should be replaced.

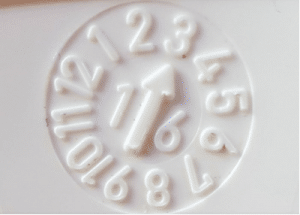

Hard Hat: Hard hats can last up to 5 years on the shelf, but it is recommended that you replace your hard hat every 2-3 years and immediately if they sustain impact. If debris collides with your hard hat, it will no longer be effective protection for your head, and you must replace it. Every hard hat has an expiry date. To check the expiry date, you first need to find out when the hard hat was manufactured. It will be stamped on your hard hat.

Hi-Vis Clothing: High visibility clothes are made of a fluorescent (day-glow) material with a light reflective tape. The reflective tapes contain glass beads and because of that Hi Vis tends to have a maximum number of washes. Hi-vis clothing needs to be replaced when it is faded, torn, dirty, soiled, worn, defaced, or not visible. The expected life of Hi Vis clothing is determined by the number of washes – washed once a week, it would last approximately 6 months, washed once a month, it would last 2 years.

Safety Harnesses and Lanyard: Safety harnesses and lanyards have a 10-year lifespan from the date of manufacture, which must be written on the PPE’s compliance label along with the date of destroy. Although, the majority of harnesses and lanyards do not make it to the end of that 10-year lifespan, and are tagged out of service well before then. Harnesses and lanyards must be inspected before each use. They must also be inspected by a height safety equipment inspector every six months or as per the manufacturer’s instructions to ensure good working order.

Hearing Protection: According to OHS people should wear a hearing protector if the noise or sound level they are exposed to is close to or greater than the occupational exposure limits (OEL) for noise. For most jurisdictions, this occupational exposure limit is 85 decibels (A-weighted) or dBA.

However, you should also know when to replace your ear plugs, or earmuffs. Single use ear plugs need to be discarded after use. A multiple use earplug can last for 2-4 weeks, and earmuffs should be examined regularly for cracks and leaks in the ear cushion and earcups. As ear cushions and foam inserts can degrade over time, replace these every 6-8 months under normal wear, or every 3-4 months with heavy use or in humid/extreme climates.

We hope that this guide has been helpful to let you know when you should be checking your PPE to ensure it is still safe for work. If you or your colleagues have questions or concerns regarding PPE and its lifespan, please reach out to our team! Our HSE experts are happy to advise you.

3 Comments

Leave a Reply Cancel reply

Let's Chat! Reach Out to Our Team

How Can We Help You?

Contact us at JADA Solutions (HSE) Inc. to speak with one of our professionals!

Newsletter

What is Sick Building Syndrome? 🏢

Learn about some common causes, risk factors and prevention methods in our latest blog post:

#sickbuildingsyndrome #indoorairquality #iaq #hseblog

Did you know that March is Workplace Eye Safety and Wellness Month? 👀

Our latest blog post covers common risks & tips for optimal Eye Health and Safety. ✍

Learn more:

-

#eyehealth #eyesafety #eyewellness #healthandsafety #hse

Nice blog

[…] Lifespan of Personal Protection Equipment (PPE) […]

[…] Lifespan of Personal Protection Equipment (PPE) […]